The cardan shaft plays a major role in all rear wheel drive vehicles. Its function is to transfer torque from the gearbox to the gearbox rear axle, which distributes it already along the semiaxes. Such a mechanism also requires close attention, so in this article we will consider why the outboard bearing is being replaced. cardan shaft VAZ and how to do it?

Why replace the cardan bearing?

The bearing is a structure of two bushings of different diameters, between which there are metal balls treated with grease. The second bearing race has a fastening device and is suspended from the bottom of the car. That is why it is called suspended. The internal cavity of the part is closed with a special insert. It protects the lubricant from external influences such as dust, moisture and other foreign particles. When this insert fails, bearing wear accelerates rapidly, which must be periodically monitored.

This element performs the following functions: reducing the level of vibrations of the cardan shaft and ensuring its rotation without any loads and deviations from the given rotation trajectory. In the process of driving a car, you can hear a sharp and loud knock, which is well transmitted through the seats of the car, and then develops into a certain vibration or even beating. Gradually, the knock decreases, but the vibration remains - this means that you can confidently declare a malfunction of the outboard bearing.

Video - Noise in outboard bearing

How to change an outboard bearing on a VAZ 2107?

As soon as you hear the characteristic sounds of bearing failure, evaluate appearance bearing. To do this, you need to look where it is located. Most often, a failed bearing has minor external damage in the form of a bent protective insert, and traces of lubricant are visible on the housing. After that, you can start replacing the part.

Replacement order:

This is how the outboard bearing of the VAZ driveshaft is replaced. As you can see, this is not a complicated operation at all and requires only the space and the availability of the appropriate tool from you.

The design of the cardan outboard bearing is a mechanism that allows you to rotate and move parts in space. The bearing device secures the axle by supporting the shaft and absorbing the radial load. But, like other components, sooner or later on any car it is necessary to change the cardan outboard bearing.

How to establish the faulty condition of the cardan outboard bearing of your own car?

The presented bearing serves as an additional support and dampens the likely vibrations during the rotational movements of the cardan shaft. If the bearing is not systematically lubricated, then after twenty to thirty thousand kilometers it may be necessary to change it to a new one.

Sometimes during a coasting trip, a strange sound occurs, resembling a hum, coming from an unclear source. Such noise may be a sign that the bearing is in a bad condition.

It is important to distinguish between the knock of the cross with the bearing rumble. Usually, a knock occurs when you touch the structure - a harsh, dull steel sound. And the buzz, which resembles the rattle of wheels on a snowy surface, is accompanied by trembling, and is felt only at speed.

After driving the car onto the lift device, you will need to make sure that extraneous noise comes directly from the outboard cardan bearing area. Noise may accompany jitter.

When the car owner makes sure that the beating, trembling and all sorts of twitches come from this zone, then it is necessary to unscrew the fixing bolts and lower the cardan shaft to the ground surface. But you need to be careful - the joint shaft of the cardan shaft should appear from the transfer case and the oily liquid will begin to drain from there. After that, you need to check the bearing for the presence of play. If the mechanism is in good condition, then there should be no play.

Instrument preparation

Replacing an automobile bearing of an outboard cardan is quite real even without the assistance of car service employees. The main thing is to carefully look at the book, which describes how to repair and operate a particular vehicle. You also need to own the right tool and have a lift or overpass at your disposal. Vinegar solution or a special liquid may be required to decoke the fixing bolts if they have become rusty.

Replacing an automobile bearing of an outboard cardan is quite real even without the assistance of car service employees. The main thing is to carefully look at the book, which describes how to repair and operate a particular vehicle. You also need to own the right tool and have a lift or overpass at your disposal. Vinegar solution or a special liquid may be required to decoke the fixing bolts if they have become rusty.

In principle, changing the outboard bearing of a cardan VAZ-2107 or VAZ-2106 will not differ much from replacing the same component on a Ford or Toyota. The scheme is similar everywhere, with some differences, but not cardinal.

To replace the bearing, you will need two open-end wrenches of 12 and 13 mm, a hammer, a metal tip, and at the same time pliers, thanks to which it will be possible to remove the retaining rings. Do not forget about a special bearing puller, without which such a process is simply not feasible.

Car owners may have a question: can the outboard bearing be repaired? Yes it is possible. But there are 2 options here - either the bearing housing is disassembled for lubrication, or the bearing is replaced directly. In the second case, this is more appropriate, but only if it is not difficult for the car owner. In particular, for Toyota the following scenario is possible - the price of a new spare part costs 1500-6000 rubles, and a simple bearing of the same size costs 100-300 rubles. Here you can save.

Anyone who disassembles the structure for the first time can follow the following recommendation: it is important to remember what is unscrewed from where, what is removed from where, bolts and nuts should be put in a jar or box. If they do not unscrew, then it is necessary to soak them with a special liquid, otherwise you can either strip the thread or completely break off the bolts.

How is a bearing replaced?

VAZ "5-ka", "6-ka" and "7-ka" have a similar chassis design, because the rules for mounting and changing the bearing are suitable for all of the listed models.

First, you need to put the vehicle on the inspection hole and remove the cardan shaft, and at the same time dismantle the cross (thanks to the 27 key, the bolt is unscrewed). We must not forget that the nut does not need to be completely removed - it is necessary to leave a little space directly on the thread in order to subsequently press out the fork.

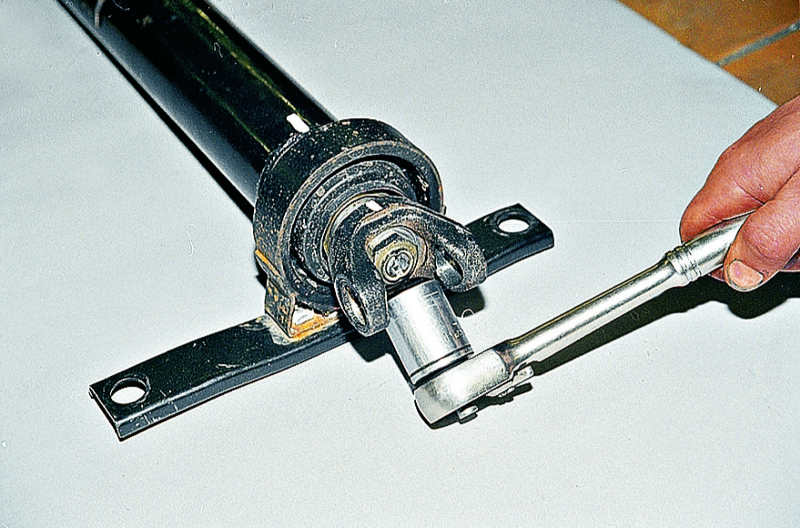

After that, you will need a puller. It can be of a different device - during the selection of this part, you must definitely ask the dealer about which particular model vehicle it is intended for. Thanks to the puller, the cardan shaft yoke is pressed in. It is possible that such a part may jam and not stick out. For this, a hammer is used. There is no need to knock too hard, otherwise both the plug and the puller will become faulty. After that, the necessary part is pressed out, the support plate is removed.

Next, the bearing is pressed directly from the shaft. To do this, you need to find two corners (50x50) and with their help, simultaneously with support on the cardan, press out the worn spare part. If necessary, you can take a steel tip and easily beat with a hammer through it. Everything, the bearing is removed.

Next, the bearing is pressed directly from the shaft. To do this, you need to find two corners (50x50) and with their help, simultaneously with support on the cardan, press out the worn spare part. If necessary, you can take a steel tip and easily beat with a hammer through it. Everything, the bearing is removed.

After removing the outboard cardan bearing, you need to get the retaining ring and mud reflective washers. Now you can start installing the new one. spare part intended for replacement.

Installation is carried out in a similar way. But there is one thing to keep in mind here: quality replacement you need to lubricate the new part. Otherwise it will appear extraneous sound after replacing the propeller bearing. Usually, manufacturers lubricate the part in advance, but this is not quite enough so that the sound does not appear after changing the cardan outboard bearing. To ensure the car has a good rotational movement of the cardan shaft, it is necessary to carefully pry off the bearing cap (wall) using an awl and process it. After that, the new part is ready for installation. If it is noticed that this spare part scrolls with hooks, then it must be replaced with another one, since the part is either defective or fake.

Following these instructions, the car owner can easily change the worn-out spare part for a new one, guaranteeing own car long and trouble-free operation.

One of the structural elements of the cardan shaft is an outboard bearing. It performs the function of maintaining driveline consisting of two or more parts. The propeller shaft support consists of a metal housing with holes for attaching to the frame, a ball bearing and a damper rubber to compensate for small vibrations.

Like any part of the vehicle, the cardan support can become unusable. Often, when a support bearing fails, neighboring parts become unusable. Therefore, in case of outboard wear, we recommend contacting our specialists who will diagnose and determine all the malfunctions that could be caused by its breakdown.

Sale and replacement of cardan support

If you require propshaft bearing replacement with a guarantee, our experts will help you with the solution of this problem. TriadaKardan LLC has a wide range of bearings for sale for cargo cardans and cars, and also provides a six-month warranty for all work and spare parts ordered in our service center.

In order to pick and buy propeller shaft outboard bearing with us, leave a request or give us a call. You can also use our catalog of outboard bearings and choose the right spare part yourself. We value our reputation, therefore, for repair and sale, we use only high-quality bearings, proven by experience.

Signs of breakdown

The main signals that the outboard bearing is out of order and need repair or replacement are:

- A sharp blow to the body, which in some cases is felt by a person through the car seat;

- Characteristic hum that increases with increasing speed;

- Creak or "squeak" of the bearing, which may disappear and appear under certain conditions;

- Vibration when the damper rubber peels off from the cage or bearing.

It often happens that a newly installed outboard bearing fails after a few thousand kilometers. This is usually due to an unqualified replacement of the spare part. Incorrect reassembly of the universal joint or an error in the selection of the bearing leads to a quick breakdown. The reason for the frequent breakage of the outboard bearing may be due to the wear of the set under the outboard bearing.

Outboard bearing catalog

You can do it yourself selection of cardan support by size in our catalogue. Below is a range of spare parts, the cost of which is relevant when performing repairs at TriadaKardan LLC and for bulk purchases. Retail prices for outboard bearings of the cardan shaft, please call in Moscow. If the part you are interested in is not listed, call us, the company's specialists will help with its acquisition.

On cardan shaft in the car there is an important structural element called "suspension bearing". It is necessary to maintain the correct position of the cardan shaft and axis, as well as to perceive and transfer the load, both axial and radial. Such a product provides rolling, rotation and linear movement along the axis, produced with the least resistance.

The outboard bearing structurally consists of a metal housing with a hole in it, into which a bushing is inserted. The gap formed between them is filled lubricant, which allows easy movement of the main parts relative to each other. This significantly reduces the friction of the elements against each other, reduces the amount of thermal conductivity, protects against negative environmental influences, and also improves the reliability and efficiency of the mechanism.

The main operational features and design advantages that an outboard bearing has:

- vibration resistance;

- noiselessness;

- the ability to work with significant radial and angular loads;

- effective protection against aggressive environments;

- ease of repair.

The first signs of a malfunction are considered to be the body, which can be felt through the seat, some time after that, a hum and vibration may appear. Most common problem becomes aging and wear of the gum. In this case, you must immediately contact a car service, since the replacement of the outboard bearing is possible only when the entire cardan shaft is removed.

1. If possible, purchase bearings in specialized car dealerships that guarantee the availability of high-quality and new equipment. Since when buying a used element, you cannot even assume its service life, which means you cannot say when it will fail if it is installed on your car.

2. Choose only original spare parts that match your car. If the required model is no longer in production, then you should contact the manufacturer. In such cases, she gives some guidance and gives an example of a replacement that is as close to the original design as possible.

3. Check for sufficient lubricant. Outboard bearing could already be filled with lubricant at the factory, or it could come out "dry". In the first case, immediate installation is possible, in the second, some additional steps must be taken to fill the bearing with grease. These activities are not complex and are often described on the product label or packaging.

4. When buying, identify the absence of play. It is believed that the presence of backlash on a new bearing is a manufacturing defect, and low-quality products are screened out at the factory. However, no one is immune from mistakes. Therefore, immediately with the seller, check the integrity and serviceability of the purchased structure.

The outboard bearing is an integral part of the cardan shaft, therefore, the service life of this part of the structure directly depends on the nature of the operation of the vehicle as a whole.